Project Summary

“The team at PSC is always on it, their product performs extremely well, and they have made my job easier. I definitely get my money’s worth when working with PSC.”

Solution Spotlight

About York Wallcoverings.

York Wallcoverings is the oldest and largest wallcovering producer in the United States, manufacturing residential wallpaper, commercial wallcoverings, and wall decals that can be found across 85 countries worldwide. For over a century, York has been manufacturing wallpaper from the same factory location in Pennsylvania. York is one of the only printing companies in the world to own and operate five different types of printing presses.

The Problem.

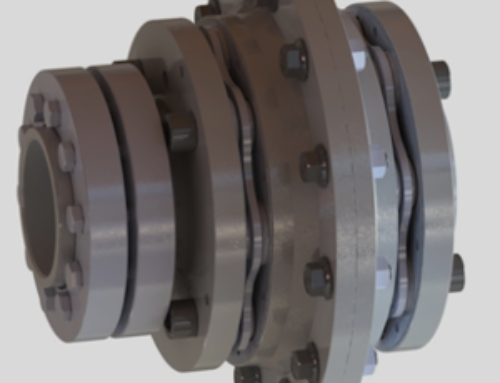

Operating and maintaining these printing presses and the craft of using them is held in the highest regard by all at York. During operation, the presses are driven by electric motors. The motor for each press drives a gearbox, and the gearbox drives the roller of the press. A coupling is required to transmit the torque and allow misalignment between the gearbox and the roller.

Prior to working with PSC, York used cruciform disc couplings between the gearbox and the roller. However, the coupling life was not meeting the requirements of the operation, and the change-over time for the couplings was exceptionally long.

This resulted in higher costs for the operation and downtime that needed to be reduced. The cruciform disc couplings also did not have the flexibility needed to allow the rollers to adjust position during operation, and as a result, there were challenges maintaining product quality.

PSC’s Solution.

When York contacted PSC, PSC quickly focused on understanding York’s coupling needs and the needs of the operation. The team at PSC specified a Series 57 coupling that provides significant improvements. The Series 57 coupling offers much greater flexibility and much lower restoring forces allowing the rollers to be positioned as needed during operation making it much easier to meet quality requirements. Also, York was able to extend the coupling life by over 75% while reducing change over time by 80%. This allows York to significantly increase uptime of the presses and efficiently support any required changeovers.