Project Summary

“We are leaps and bounds ahead of what we started with, and I am excited about the future.”

Solution Spotlight

About Custom Dredge Works.

Custom Dredge Works is a world leading producer of dredges with over 40 years of metal fabrication experience. Custom Dredge Works’ focus is to design, engineer, and manufacture dredges that offer the highest value and the greatest return on investment found anywhere. The team at Custom Dredge Works has a culture of innovation and operational excellence which is evident in the quality of every dredge delivered. PSC Couplings share this same culture, so when Custom Dredge Works called PSC Couplings for assistance with disc coupling and driveline optimization, it was a natural fit.

Collaborative Effort

Custom Dredge Works and PSC couplings quickly worked together to define the goals of the project. The goals included a more efficient assembly and service process, longer driveline life in the field, and lower total cost. After the goals were established, a joint team reviewed the current state of the driveline design to understand the challenges. The team decided to take a fresh look at every aspect of the disc couplings and driveline from manufacturing, installation, field operation, and service. According to John Jones, President of Custom Dredge Works, “The team was challenged with improving the driveline as an entire system. This included the disc couplings as well as the other components of the driveline. It is a system, and all components must work together seamlessly.”

Focus on Innovative Solutions

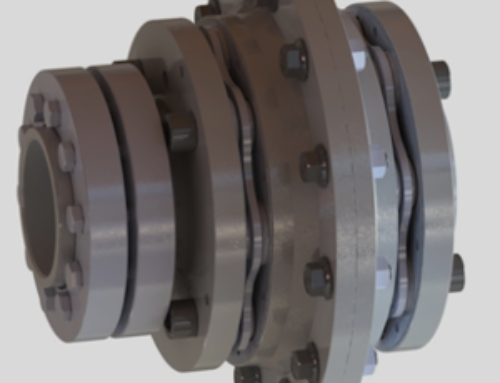

Once the goals were established, the team defined options for improving the design. To improve the life of the driveline in the field, the team selected PSC’s Series 57 disc coupling. The Series 57 has the highest torque density in the industry and is able to transmit higher torque while withstanding the dynamic loading the driveline experiences during dredging operations

Next, the team reviewed design options to integrate the couplings into the driveline while improving the installation process. The improved design eliminates the need for welding the driveline. The design also allows the coupling hubs to move freely during installation which allows the driveline sections to be set in the optimal positions. To improve ease of service, the couplings incorporate all standard fasteners at each connection point. Finally, the team defined a process for driveline setup to be used during initial installation and in the field. This process confirms setup alignment and indicates if any adjustments are necessary.

Implementation and Results

The team reviewed the improvement options and confirmed the final design. Custom Dredge Works and PSC Couplings worked closely together during the manufacturing and integration of the design. Both Custom Dredge Works and PSC Couplings were impressed with PSC Series 57 Disc Coupling the results. Installation time has reduced by over 70%, and setup now takes minutes instead of hours. The elimination of welding saves a considerable amount of time and improves the quality of the driveline. The Series 57 disc couplings improved coupling life by over 50%. And all of these improvements have lowered the total cost while delivering a more reliable driveline system. According to Dave Olson, President of PSC Couplings, “The input from both companies was critical in defining the design options that would best meet the goals. Each team member had different perspectives and input, and it was this combination that allowed the team to be successful.” Mr. Jones added, “We are leaps and bounds ahead of what we started with, and I am excited about the future.”

To learn more about disc coupling solutions from PSC Couplings, contact us.