Series 57 Key Features.

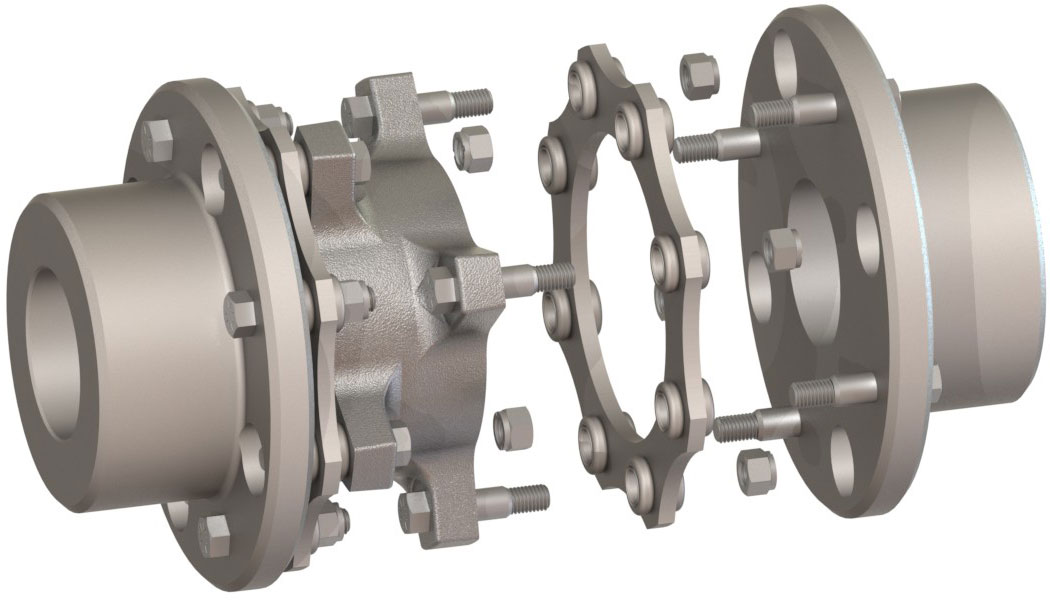

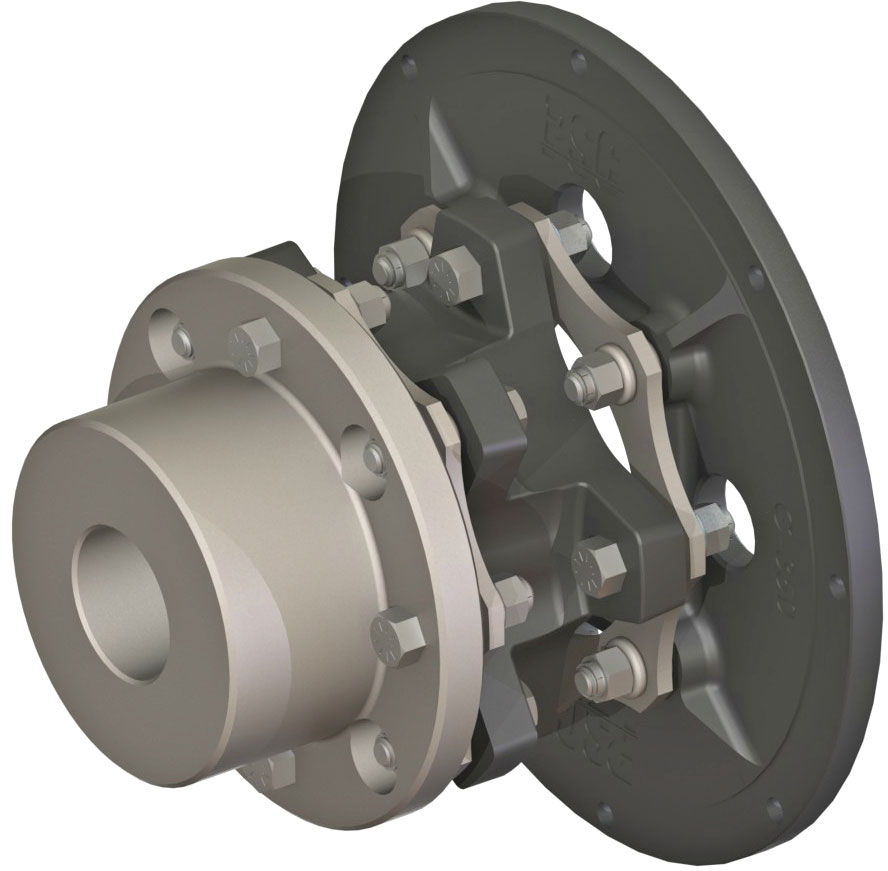

Standard Design:

- Ultra-high strength stainless spring steel discs

- Standard metric 12.9 hardware for easy maintenance

- AGMA Class 9 as manufactured (see how we accomplish this)

- 4140 alloy material for cold weather applications

Optional Features:

- AGMA Class 10 and 11 (click for more information)

- API-671 compliant

- Many options available upon request

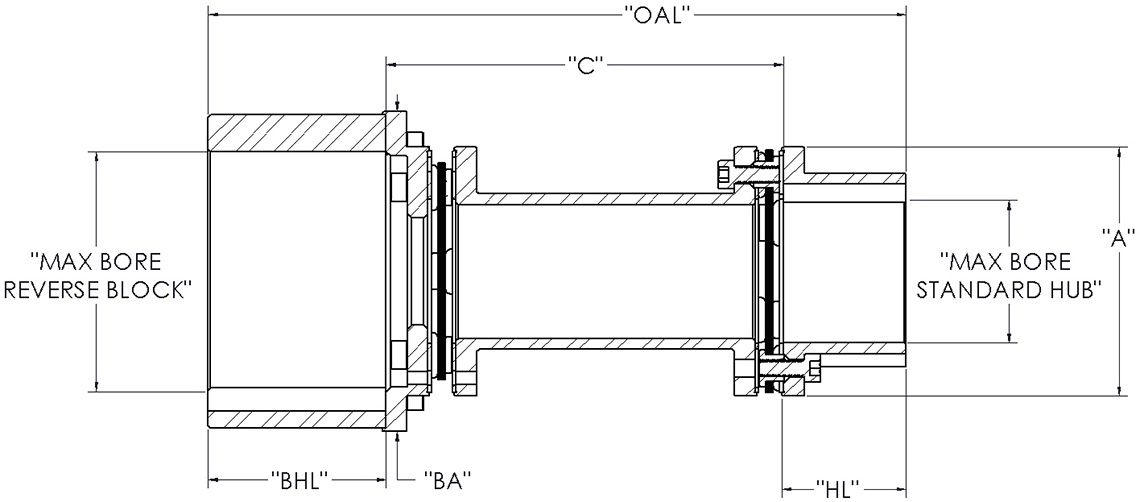

Diagram Series 57

Series 57 Competitive Replacement Guides.

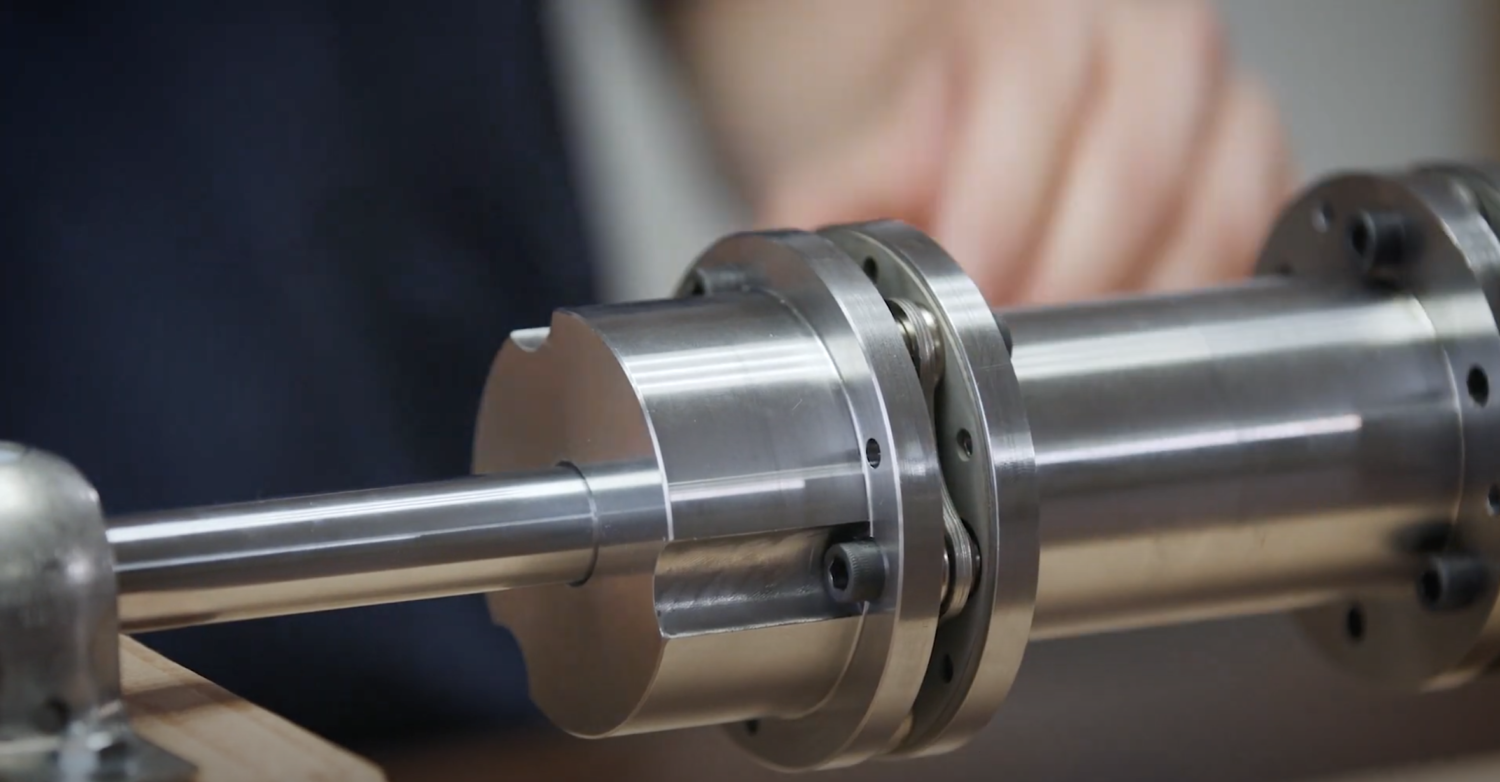

Product Videos.

Series 57 Specific Details.

| Size | Continuous Torque (in-lbs) | Continuous Torque (Nm) | Peak Torque (in-lbs) | Peak Torque (Nm) | Max Bore (in) | Max Bore (mm) | Max Bore Reverse Block Hub (in) | Max Bore Reverse Block Hub (mm) | Max Angular Misalignment (deg ) | Max Axial Misalignment (in) | Max RPM AGMA 9 | Max RPM AGMA 10 | Max RPM AGMA 11 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 516 | 3,000 | 339 | 4,000 | 452 | 1.50 | 38 | 2.63 | 67 | 0.5 | +/- 0.018 | 4,800 | 20,000 | 38,000 |

| 696 | 7,000 | 791 | 9,333 | 1,055 | 2.00 | 52 | 3.38 | 86 | 0.5 | +/- 0.024 | 4,800 | 15,000 | 29,000 |

| 906 | 16,000 | 1,808 | 21,333 | 2,410 | 2.50 | 65 | 4.25 | 108 | 0.5 | +/- 0.031 | 4,800 | 12,000 | 22,500 |

| 1236 | 43,800 | 4,948 | 58,400 | 6,598 | 3.50 | 89 | 6.25 | 158 | 0.5 | +/-0.042 | 3,600 | 10,000 | 19,000 |

| 1358 | 66,000 | 7,457 | 88,000 | 9,943 | 4.00 | 102 | 6.50 | 165 | 0.5 | +/- 0.046 | 3,600 | 8,000 | 15,000 |

| 1708 | 142,500 | 16,100 | 190,000 | 21,467 | 5.00 | 127 | 8.00 | 203 | 0.5 | +/- 0.058 | 3,600 | 7,000 | 11,500 |

| 2048 | 264,000 | 29,828 | 352,000 | 39,771 | 6.00 | 152 | 10.00 | 254 | 0.5 | +/- 0.070 | 3,600 | 6,000 | 9,750 |

| 2558 | 474,000 | 53,555 | 632,000 | 71,406 | 7.00 | 180 | 12.50 | 318 | 0.5 | +/- 0.088 | 3,600 | 5,000 | 7,900 |

| 3008 | 950,000 | 107,336 | 1,266,667 | 143,114 | 8.50 | 215 | 14.00 | 356 | 0.5 | +/- 0.103 | 1,800 | 3,600 | 6,800 |

| 3438 | 1,500,000 | 169,477 | 2,000,000 | 225,970 | 9.75 | 250 | 17.00 | 432 | 0.5 | +/- 0.118 | 1,800 | 3,600 | 5,900 |

| 4048 | 2,250,000 | 254,216 | 3,000,000 | 338,954 | 12.00 | 300 | 20.00 | 508 | 0.5 | +/- 0.139 | 1,800 | 3,600 | 4,950 |

| 4628 | 3,125,000 | 353,078 | 4,166,667 | 470,770 | 13.00 | 330 | 22.00 | 550 | 0.5 | +/- 0.159 | 1,500 | 3,600 | 4,200 |

| ____ | _________ | _________ | _________ | _________ | _____ | _____ | ___________ | ___________ | ___________ | ___________ | _________ | _________ | _________ |

| Size | "B" (in) | "B" (mm) | "HL" (in) | "HL" (mm) | "A" (in) | "A" (mm) | Minimum Std "C" (in) | Minimum Std "C" (mm) | Imperial Std "C" (in) | Metric Std"C" (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| 516 | 2.03 | 51.6 | 1.41 | 35.7 | 2.73 | 69.3 | 1.81 | 46 | 3.5, 4.38, 5.0 | 100, 140 |

| 696 | 2.75 | 69.9 | 1.72 | 43.6 | 3.50 | 88.9 | 2.33 | 59.2 | 3.5, 4.38, 5.0 | 100, 140, 180 |

| 906 | 3.50 | 88.9 | 2.20 | 56.0 | 4.64 | 117.9 | 2.91 | 73.9 | 3.5, 4.38, 5, 7.5 | 140, 180 |

| 1236 | 5.00 | 127.0 | 3.18 | 80.8 | 6.63 | 168.3 | 3.92 | 99.6 | 7.5 | 180, 250 |

| 1358 | 5.38 | 136.7 | 3.73 | 94.8 | 6.88 | 174.8 | 3.92 | 99.6 | 7.5 | 180, 250 |

| 1708 | 6.81 | 173.0 | 4.71 | 119.5 | 8.69 | 220.7 | 5.33 | 135.4 | 7.5, 8.0 | 180, 250 |

| 2048 | 8.25 | 209.6 | 5.69 | 144.5 | 10.63 | 270.0 | 6.02 | 152.9 | 9.0 | 250 |

| 2558 | 10.00 | 254.0 | 6.85 | 174.1 | 12.94 | 328.7 | 8.04 | 204.2 | 12.0 | - |

| 3008 | 11.75 | 298.5 | 8.31 | 211.1 | 15.46 | 392.7 | 9.88 | 251 | 15.0 | - |

| 3438 | 13.50 | 342.9 | 8.76 | 222.5 | 17.63 | 447.8 | 11.46 | 291.1 | 18.0 | - |

| 4048 | 16.00 | 406.4 | 10.70 | 271.7 | 20.88 | 530.4 | 14.37 | 365 | 18.0 | - |

| 4628 | 18.63 | 473.1 | 12.70 | 322.5 | 23.75 | 603.3 | 16.04 | 407.4 | 24.0 | - |

| _____ | _____ | _____ | _____ | _____ | _____ | _____ | ________ | ________ | ________________ | ______________ |

| Size | Weight @ Max Bore min "C" inch (lbs) | Weight @ Max Bore min "C" mm (kg) | Inertia @ Max Bore min "C" inch (lb-in2) | Inertia @ Max Bore min "C" mm (kg-m2) | Torsional Stiffness min "C" inch (in-lbs/rad) | Torsional Stiffness min "C" mm (Nm/rad) | Min Torsional Stiffness Tuned "C" in (in-lbs/rad) | Min Torsional Stiffness Tuned "C" mm (mm-Nm/rad) |

|---|---|---|---|---|---|---|---|---|

| 516 | 2.29 | 1.04 | 2.21 | 6.47E-04 | 3.52E+05 | 3.98E+04 | 1.16E+05 | 1.31E+04 |

| 696 | 5.21 | 2.36 | 8.68 | 2.54E-03 | 8.15E+05 | 9.21E+05 | 3.16E+05 | 3.57E+04 |

| 906 | 11.6 | 5.26 | 32.8 | 9.60E-03 | 1.41E+06 | 1.59E+05 | 5.94E+05 | 6.71E+04 |

| 1236 | 32.7 | 14.8 | 181 | 5.295E-02 | 1.83E+06 | 2.07E+05 | ||

| 1358 | 35.9 | 16.3 | 226 | 6.61E-02 | 7.00E+06 | 7.91E+05 | 2.92E+06 | 3.30E+05 |

| 1708 | 78.9 | 35.8 | 815 | 0.24 | 1.08E+07 | 1.22E+06 | 5.87E+06 | 6.63E+05 |

| 2048 | 138 | 62.6 | 2,058 | 0.60 | 1.54E+07 | 1.74E+06 | 9.51E+06 | 1.07E+06 |

| 2558 | 280 | 127 | 6,131 | 1.79 | 2.23E+07 | 2.52E+06 | 1.47E+07 | 1.66E+06 |

| 3008 | 458 | 208 | 14,440 | 4.23 | 2.90E+07 | 3.28E+06 | 2.03E+07 | 2.29E+06 |

| 3438 | 671 | 304 | 27,544 | 8.06 | 3.64E+07 | 4.11E+06 | 2.61E+07 | 2.95E+06 |

| 4048 | 1,158 | 525 | 68,124 | 19.93 | 4.63E+07 | 5.23E+06 | 3.79E+07 | 4.28E+06 |

| 4628 | 1,811 | 821 | 134,048 | 39.22 | 5.59E+07 | 6.32E+06 | 4.55E+07 | 5.14E+06 |

| ______ | _________________ | _________________ | _________________ | _________________ | _________________ | _________________ | ______________ | _________________ |