The Need for Electrical Insulation

Electric motors often develop voltage differences between the shafts of the motors and the shafts of the connected equipment. Machinery manufacturers can use electrically insulated couplings to prevent electric arcs across bearings and other components resulting from currents caused by the voltage differences.

PSC’s Electrically Insulated Couplings

PSC’s electrically insulated couplings have several design features that provide electrical insulation and superior performance.

Electrical Insulation

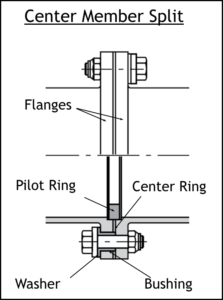

- Typically, the center member of the coupling is split and flanges are incorporated on both ends. This flanged joint may be placed at the middle of the center member or at one end (for example with high torque applications).

- A center ring is placed between the flanges to provide isolation.

- Bolts securing the flanges are insulated on the bolt head side by bushings and washers.

Alignment

- Pilot counterbores are precisely machined in both flanges, and a pilot ring accurately positions the flanges with respect to each other.

Torque Rating

- All electrically insulated components (bushings, washers, center ring, pilot ring) are manufactured from a high-pressure fiberglass composite material. This material does not degrade under high compressive stresses and allows the required torque to be transmitted.

- The flange diameter and number of bolts are selected based on the torque carrying requirement of the coupling and are designed not to limit performance. Due to PSC’s high toque density, there may be couplings where the flange diameter may be larger than the diameter of the flanges connecting the disc packs.

Please contact PSC for more information on electrically insulated couplings.