Product Overviews.

G-Series

GA Model for Gas Compression

Interchangeable with Thomas AMR and TB Woods HSH with similar mass elastic characteristics

- Alloy hub and stainless steel disc are standard

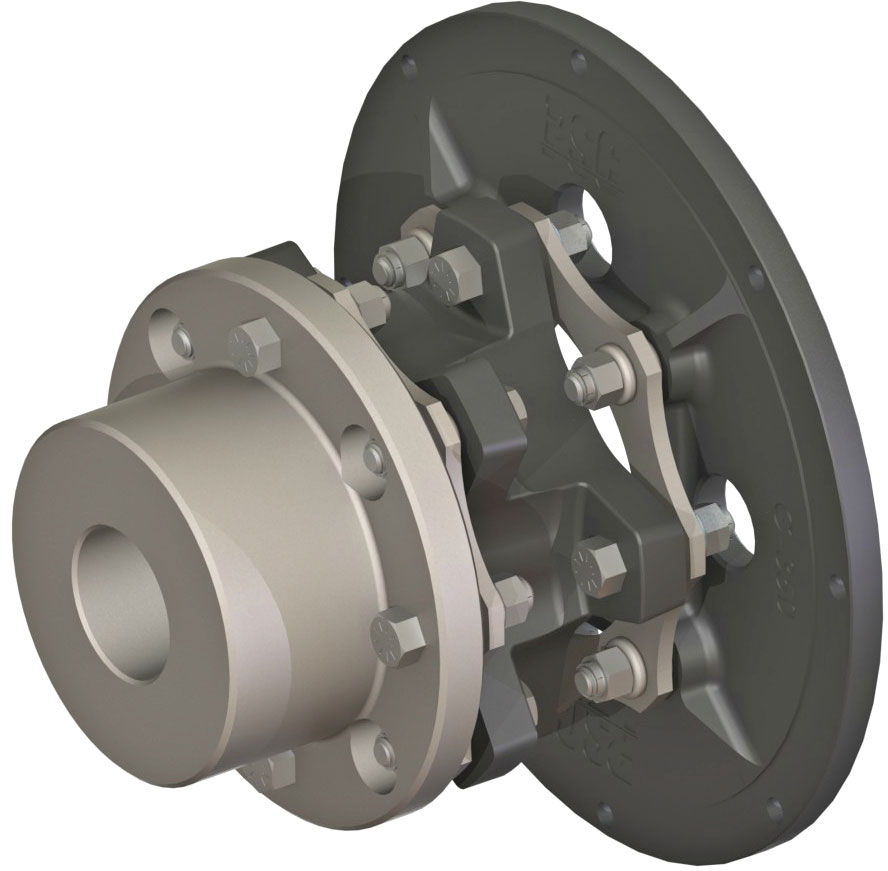

G-Series

GC Model for Gas Compression

Interchangeable with Thomas CMR and TB Woods FSH with similar mass elastic characteristics

- Alloy hub and stainless steel disc are standard

Product Demo Video.

Product Design Details.

Interchangeable with Rexnord Thomas and TB Woods

- Positioned to be interchangeable with the gas compression couplings from Rexnord Thomas and TB Woods with similar mass, inertia, and stiffness

Stainless steel discs and alloy steel hubs are standard

- Improved ease of installation with unitized disc packs

- Reduced disc flaring and disc flexing forces with scalloped discs

Custom options available

- Ability to tune mass, inertia, and stiffness with custom design options.

- API compliant versions available

Product Advantages.

Installation is Quick, Easy, and Accurate

Gas Compression

Due to the tunable stiffness, PSC’s disc couplings may be a good fit in

packages where detuners can be avoided or where an elastomer coupling is recommended but a disc coupling is preferred.

packages where detuners can be avoided or where an elastomer coupling is recommended but a disc coupling is preferred.

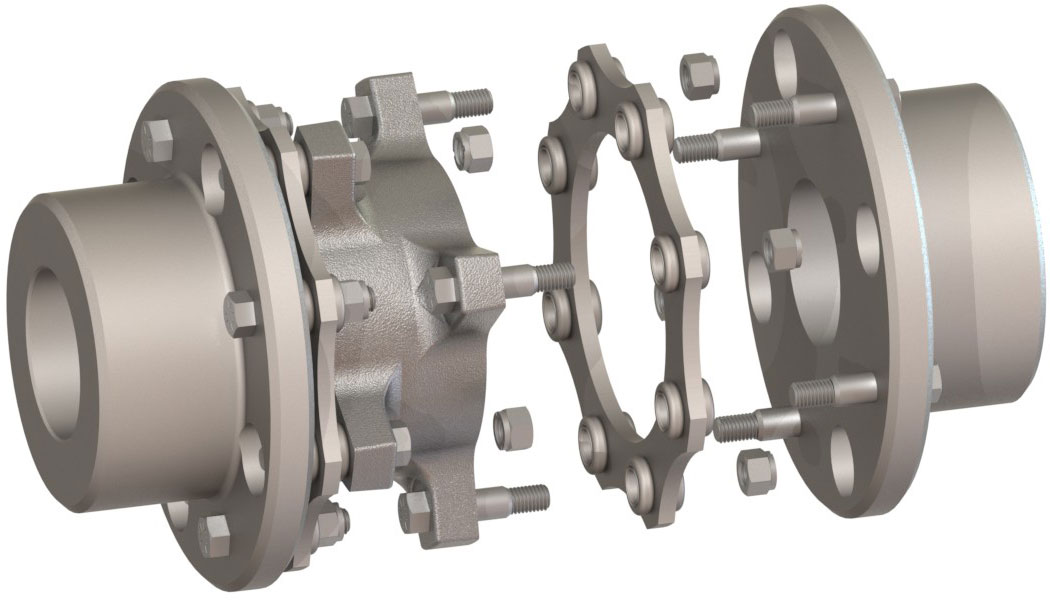

Unitized Disc Packs

- No loose washers, no loose discs

- Disc pack is produced as one

piece - Stainless steel discs and

electroless nickel plated

bushings and washers as

standard

Bushing Sleeve Guides Bolts

- Bolts easily go through disc

pack bushings into flange

holes - No need to struggle with

bolt installation or removal

Hub, Center Member, and Flywheel Industry Standard Design

- Cast flywheel and center member

- Industry standard hardware design

- Upgraded alloy steel hub as standard

Contact Us Today.

We work with you to find the ideal solution for your coupling needs.